SCHNELLER VERSAND

1-3 Tage Lieferzeit

Unser engagiertes Versandteam packt und versendet eure Bestellungen normalerweise innerhalb eines Werktages. Über die genauen Lieferfristen könnt ihr euch hier informieren.

FAIRE PREISE

Sparen macht Freude

Wir halten nichts von überteuerten Produkten und so ist auch unsere Preispolitik. Gute Schnäppchen könnt ihr im % SALE oder bei Newsletter-Rabattaktionen machen.

GLOSSAR

Von A-Z informiert

Hier findet ihr Wissenswertes rund um Parfums und Kosmetik. Was ist ein Absolue, wie wirkt Aloe vera und woher kommt Ylang-Ylang? Unser Diktionär gibt Antworten.

100% ORIGINALWARE

Direkt vom Hersteller

Wir von dambiro garantieren, dass alle hier verkauften Produkte zu 100 % Originalwaren sind. Die meisten kommen direkt vom Hersteller zu uns ins Lager.

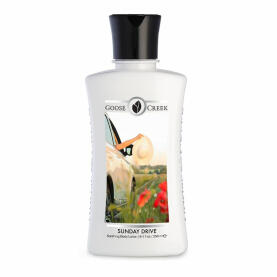

FÜR DICH UND DEIN ZUHAUSE

DÜFTE

Ob Klassiker, Trenddüfte oder Nischenparfums. Hier werdet ihr fündig.

weiter

Natur

Unsere Natur-Lieblinge. Pflegeprodukte mit natürlichen Inhaltsstoffen

weiter

Der Duft für eine erholsame Nacht! Die neue Duftlinie Fiori di Luna von Felce Azzurra wurde speziell entwickelt, um die Entspannung am Abend zu fördern.

Weil wir gute Produkte lieben! Unsere dambiro Rasierseife Vetyver erzeugt einen cremigen und reichhaltigen Schaum, der für eine komfortable und gründliche Nassrasur sorgt.

"Vintage" ist eine Gesichtspflegeserie speziell für junge Menschen. Die innovativen Produkte auf natürlicher Basis sorgen für eine frische und gepflegte Gesichtshaut.

Egal, ob lockiges, gewelltes oder krauses Haar, die Marke bietet die perfekte Pflege für jeden Haartyp.

Das neue japanische Wellness-Ritual von Tesori d'Oriente mit holzig zitrischem Unisex-Duft. Es vermittelt ein Gefühl von Ruhe, wie ein entspannter Waldspaziergang.

Für besondere Wohlfühlmomente! Aktuell haben wir die wohlig duftenden Badeschäume von Cléo im Preis reduziert. Also schnell noch zugreifen.

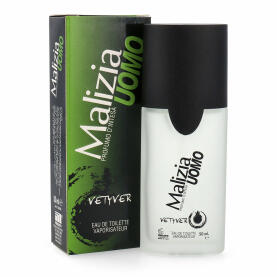

Italienische & internationale Parfums, die du lieben wirst

Unser umfangreiches Parfum-Sortiment an italienischen und internationalen Parfum-Marken bietet eine abwechslungsreiche Auswahl und für jeden Geschmack den passenden Duft an. Neben bekannten Klassikern, findet man wahre Duftraritäten von kleinen italienischen Herstellern bis hin zu exklusiven und hochwertigen Nischendüften. Ob Damenduft, Herrenduft, Unisexduft oder Nischenduft - in unserem Webshop ist sicher für jeden das richtige Parfum dabei!

Die Geschichte des Parfums

Die Geschichte der Düfte fängt bereits bei den alten Ägyptern an. Schon in jener Zeit galt die Benutzung von Duftstoffen und Körperölen als ein Ausdruck des persönlichen Schönheitsideals. Düfte entzückten die Sinne, reinigten, schützten und zeigten gleichzeitig den materiellen Wohlstand. Somit haben sich die Düfte bis zu unserer Zeit ständig weiterentwickelt. Für die meisten gehören Düfte zum täglichen Leben dazu.

Die unterschiedlichen Parfumtypen

Ein Parfum ist ein Gemisch aus Alkohol und unterschiedlichen Duftstoffen, das zur Erzeugung eines angenehmen Geruchs dienen soll. Ein Parfum ist also quasi eine Duftkomposition, die sich über den eigenen Körpergeruch legt und mit dem man seine Persönlichkeit oder seine jeweilige Stimmung ausdrücken kann. Man unterscheidet verschiedene Arten von Parfum, je nach enthaltenem Duftanteil.

- Parfum: Diese Variante kann man auch als Essenz bezeichnen und besitzt mit 15-30% die höchste Duftkonzentration. Ein Parfum enthält kein Wasser und bereits kleinste Mengen reichen aus, um den ganzen Tag lang einen intensiven Duft zu tragen.

- Eau de Parfum: Der Duftanteil liegt hier bei 10-15% und der Duft eines Eau de Parfums ist intensiv und langanhaltend. Daher reicht hier schon eine sparsame Anwendung aus.

- Eau de Toilette: Ein Eau de Toilette enthält einen Duftanteil von rund 6-10%. Da ein Eau de Toilette leichter ist, verflüchtigt sich der Duft relativ schnell, eignet sich aber auch perfekt für den Sommer und kann großzügiger aufgetragen werden. Meist ist ein Eau de Toilette auch deutlich günstiger als ein Parfum oder ein Eau de Parfum.

Die olfaktorische Pyramide

Verändert sich der Duft eines Parfums nach einiger Zeit auf der Haut, liegt das an der dreistufigen Duftkomposition, die aus der Kopfnote, der Herznote und der Basisnote besteht und als olfaktorische Pyramide bezeichnet wird. Die überwiegende Mehrheit der Parfums ist nach dieser Duftpyramide aufgebaut.

- Kopfnote: Die Kopfnote ist das Erste, was man von einem Duft nach dem Aufsprühen wahrnimmt. Häufig dominieren zitrische Noten wie Bergamotte oder würzige Aromen und prägen den ersten Eindruck. Die Kopfnote verflüchtigt sich jedoch nach kurzer Zeit, während sich die Herznote langsam entfaltet.

- Herznote: Die Herznote entfaltet sich etwa 15 Minuten nach dem Auftragen des Parfums und hält für etwa zwei bis drei Stunden an. In der Herznote findet man häufig blumige, fruchtige, würzige oder grüne Duftnoten.

- Basisnote: Etwa eine Stunde nach dem Auftragen kann man die Basisnote wahrnehmen, die mehrere Stunden lang anhält. Meist sind holzige Noten, Amber oder Moschus in der Basisnote enthalten, aber auch orientalische Aromen wie Weihrauch oder Vanille.

Parfums können aber auch nach einer linearen Komposition aufgebaut sein, was bedeutet, dass sich alle Duftnoten gleichzeitig entfalten und sich der Duft nicht verändert.

Hochwertige Nischendüfte bei dambiro

Außergewöhnliche Parfums für Individualisten! Nischendüfte zeichnen sich durch folgende Eigenschaften aus: Sie sind exklusiv, individuell, facettenreich und einfach außergewöhnlich. Perfekt für alle, die das Besondere lieben und einen Duft suchen, der sich von der breiten Masse abhebt. Bei dambiro findet man Nischendüfte für Damen und Herren, aber auch Unisex-Düfte von vielen verschiedenen Marken wie Atkinsons, Acca Kappa, Kajal, L'Arc, sous le manteau, Rosendo Mateu, Gabriella Chieffro und vielen weiteren.

Parfum online bestellen bei dambiro

So macht Parfum einkaufen Spaß! Unser großes Sortiment bietet eine große Auswahl an internationalen Marken wie Hugo Boss, Dolce & Gabbana, Burberry, Giorgio Armani, Diesel, Christian Dior und vielen weiteren. Daneben führen wir aber auch viele beliebte italienische Marken wie Acqua di Parma, Acca Kappa, L'Amande, Paglieri oder Pino Silvestre. Auch echte Geheimtipps wie Castle Forbes oder Durance findet man in unserem gut sortierten und abwechslungsreichen Shop. Einfach online bei dambiro den persönlichen Lieblingsduft auswählen, gemütlich von der Coach aus bestellen, eine der vielen Zahlungsmöglichkeiten auswählen und den Lieblingsduft ganz bequem nach Hause liefern lassen. Aber bitte beachten, dass bereits geöffnete Parfums vom Umtausch leider ausgeschlossen sind.Proben zum kleinen Preis

Wer sich mit einem neuen Duft nicht gleich festlegen möchte, kann sich auch zunächst eine Probe bestellen. Wir bieten von vielen Parfums aus unserem Sortiment kostengünstige 2 ml Proben an. Perfekt, um den Duft erst mal zu testen!